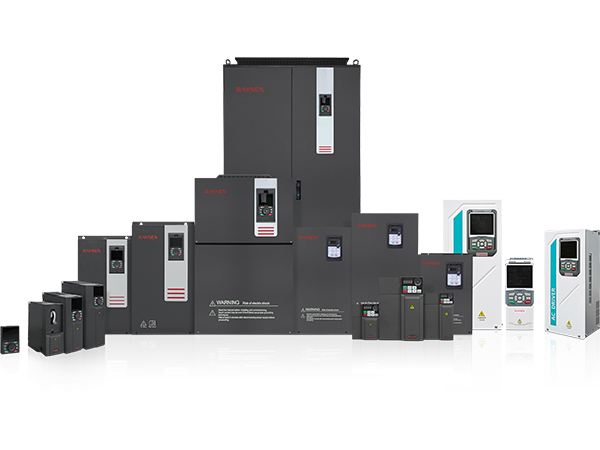

1.ความรู้เบื้องต้นเกี่ยวกับไดรฟ์ AC (ไดรฟ์ความถี่ตัวแปร) ในขอบเขตของการควบคุมอุตสาหกรรมสมัยใหม่และ......

อ่านเพิ่มเติมอุตสาหกรรมการส่งกำลัง: ไดรฟ์ความถี่แปรผันแรงดันปานกลาง

The Medium-Voltage Variable Frequency Drive (MV VFD) is a critical piece of power electronic equipment enabling precise control and efficient operation of AC motors in a wide array of industrial applications. Functioning as an interface between the power supply and the motor, the MV VFD modulates the frequency and voltage supplied to the motor, allowing its speed and torque to be varied smoothly and accurately.

Defining Medium Voltage

In the context of electrical power systems, "medium voltage" generally refers to a range of electrical potential typically between and . This range is significantly higher than the low voltage used in homes and small commercial buildings (usually under ). Motors designed to operate at these higher voltage levels are common in heavy industries such as oil and gas, mining, power generation, water treatment, and petrochemicals, where large motor horsepower (often class) is required for pumps, compressors, fans, and conveyer systems.

Core Function and Technology

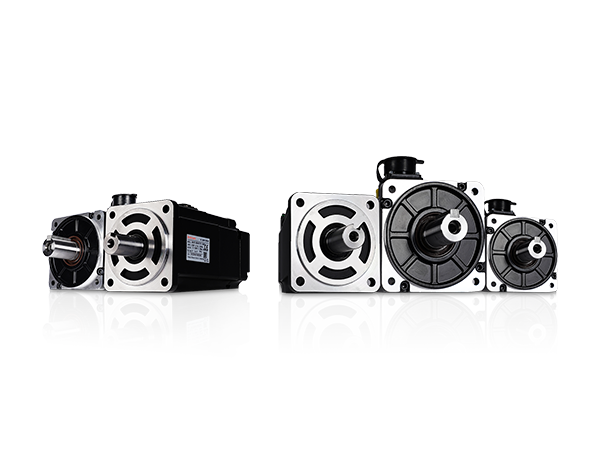

The primary function of a Medium-Voltage Variable Frequency Drive is to regulate motor speed. By controlling the frequency of the AC power supplied to the motor, the drive directly governs the rotational speed, as defined by the motor's synchronous speed formula: , where is the synchronous speed, is the frequency, and is the number of motor poles.

The internal operation of the MV VFD involves three main stages:

-

Rectification: Incoming AC power is converted into DC power.

-

DC Link: The DC power is smoothed using capacitors or inductors.

-

Inversion: The DC power is converted back into AC power with the desired, variable frequency and voltage. This is typically achieved using high-power semiconductor switches, such as Insulated-Gate Bipolar Transistors (IGBTs) or Gate Turn-Off Thyristors (GTOs) .

Due to the higher voltage levels, MV VFDs employ specialized topologies—like Multi-Level Inverters (e.g., Neutral Point Clamped (NPC), Flying Capacitor, or Cascaded H-Bridge (CHB))—to manage the voltage stress across the semiconductors and achieve a high-quality (low harmonic distortion) output waveform. The cascaded H-bridge topology is particularly popular as it allows standard low-voltage components to be series-connected to synthesize the medium voltage .

Key Advantages and Applications

The adoption of the Medium-Voltage Variable Frequency Drive offers compelling advantages that translate into significant operational benefits:

-

Energy Savings: This is often the most significant benefit. In pump and fan applications, the power consumed is proportional to the cube of the speed ( ). A small reduction in speed achieved via the VFD leads to substantial energy savings compared to traditional methods like throttling valves or dampers.

-

Process Control: VFDs allow for precise speed and torque control, optimizing processes for maximum efficiency, quality, and output.

-

Reduced Mechanical Stress: By enabling soft starting (gradual acceleration), the VFD significantly reduces the high inrush currents and mechanical shocks associated with direct-on-line starting, thereby prolonging the lifespan of the motor and connected equipment.

-

Power Quality Improvement: Modern MV VFD designs often incorporate features that minimize harmonic distortion reflected back onto the power grid, adhering to stringent power quality standards.

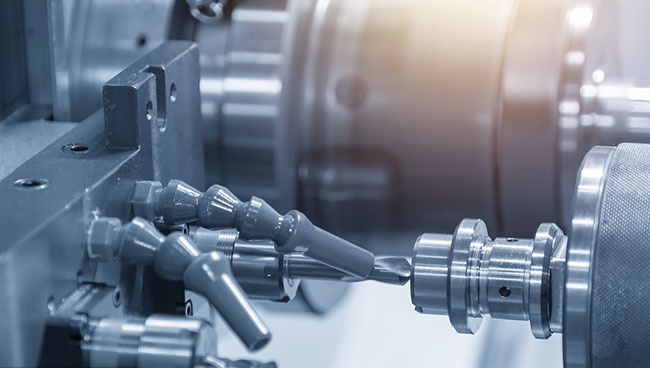

These advantages make the MV VFD indispensable in sectors requiring continuous, large-scale motor operation. Common applications include:

-

Pumps and Compressors: Optimizing flow in pipelines, refineries, and water utilities.

-

Fans and Blowers: Controlling airflow in furnaces, power plants, and ventilation systems.

-

Conveyors and Crushers: Managing material handling speed and load in mining and cement production.

-

Extruders and Mills: Providing precise speed regulation in manufacturing processes.