1.ความรู้เบื้องต้นเกี่ยวกับไดรฟ์ AC (ไดรฟ์ความถี่ตัวแปร) ในขอบเขตของการควบคุมอุตสาหกรรมสมัยใหม่และ......

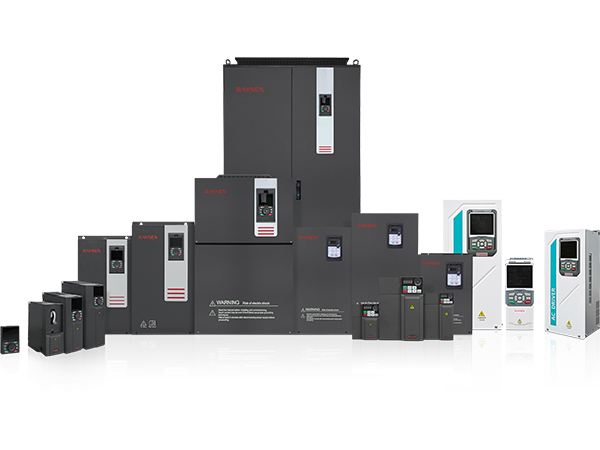

อ่านเพิ่มเติมเพิ่มประสิทธิภาพทางอุตสาหกรรมด้วยไดรฟ์ความถี่แปรผันแรงดันต่ำ

The Low-Voltage Variable Frequency Drive (VFD), often simply called a VFD or an adjustable speed drive (ASD), is a critical component in modern industrial and commercial operations. Its primary function is to control the speed and torque of a three-phase AC induction motor by varying the frequency and voltage of the electrical power supplied to the motor. By operating in the low-voltage range, typically below 690 volts (V) , these devices are widely deployed across virtually every sector that uses electric motors, from manufacturing and HVAC to water treatment and material handling.

Core Functionality and Operation

The operation of a Low-Voltage Variable Frequency Drive involves three main stages:

-

Rectifier: The incoming AC (alternating current) power from the mains is first converted into DC (direct current) power. This stage typically uses diodes or silicon-controlled rectifiers (SCRs).

-

DC Bus: The converted DC power is then stored in a capacitor bank, which acts as a filter to smooth the power and provide a stable DC voltage.

-

Inverter: This is the most crucial stage. The DC power is switched back into simulated AC power using sophisticated power electronic switches, like Insulated Gate Bipolar Transistors (IGBTs). By rapidly switching these transistors on and off using a technique called Pulse Width Modulation (PWM) , the VFD can create a variable frequency and voltage output that precisely controls the motor's speed.

Key Benefits in Application

The adoption of a Low-Voltage Variable Frequency Drive offers numerous significant advantages over traditional motor control methods:

-

Energy Savings: This is often the most compelling benefit. For applications like pumps and fans, the power required is proportional to the cube of the speed reduction (the affinity laws). By reducing the motor's speed, even slightly, the energy consumption drops dramatically. This leads to substantial cost savings and a reduced carbon footprint.

-

Process Control Improvement: VFDs allow for precise, stepless speed control, enabling better regulation of flow, pressure, temperature, or any other variable the motor is controlling. This results in higher product quality and better process stability.

-

Reduced Mechanical Stress: A Low-Voltage Variable Frequency Drive provides a soft start capability, gradually ramping the motor up to speed. This eliminates the harsh mechanical and electrical shock associated with "across-the-line" starting, extending the life of the motor, gears, belts, and the driven equipment.

-

Lower Peak Demand: By eliminating high inrush current during startup, VFDs help facilities manage their overall electrical demand, which can lead to lower utility billing charges based on peak usage.

Design and Selection Considerations

When specifying a Low-Voltage Variable Frequency Drive , engineers consider several factors to ensure optimal performance and system compatibility:

-

Motor Horsepower (HP) and Voltage: The VFD must be sized to match the motor's nominal voltage and current ratings.

-

Enclosure Rating: The VFD's enclosure must be suitable for the operating environment (e.g., NEMA 1 for indoor/clean areas, NEMA 4X for washdown/corrosive areas).

-

Control Method: Modern VFDs use various control algorithms, such as Volts per Hertz (V/Hz) , Sensorless Vector Control (SVC) , or Flux Vector Control , with the latter two offering greater torque control, especially at low speeds.

-

Harmonic Mitigation: The switching process inside the VFD can create electrical harmonics that may distort the power quality of the electrical grid. Selecting a drive with built-in or external harmonic filters is often necessary to comply with power quality standards.

In conclusion, the Low-Voltage Variable Frequency Drive is an indispensable piece of industrial technology, serving as the cornerstone for energy-efficient operation and precise, dynamic process control across the entire spectrum of motorized applications.