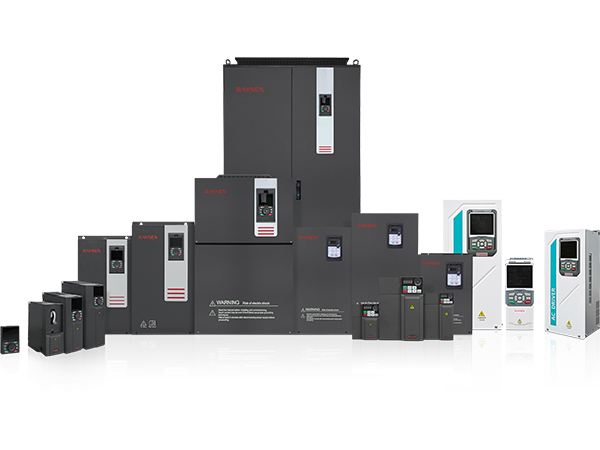

1.ความรู้เบื้องต้นเกี่ยวกับไดรฟ์ AC (ไดรฟ์ความถี่ตัวแปร) ในขอบเขตของการควบคุมอุตสาหกรรมสมัยใหม่และ......

อ่านเพิ่มเติมต้องพิจารณาคุณลักษณะของมอเตอร์ใดบ้างเมื่อเลือกไดรฟ์ AC

Selecting the right AC drive (also known as a Variable Frequency Drive or VFD) is a critical step in optimizing any motor-driven system. The drive's performance is intrinsically linked to the motor it controls, making a deep understanding of the motor's characteristics absolutely essential for proper pairing, efficiency, and system longevity.

Here are the primary motor characteristics that must be rigorously considered when choosing an AC drive :

1. Motor Type and Duty Rating

The fundamental nature of the motor dictates the drive's control capabilities and required performance:

-

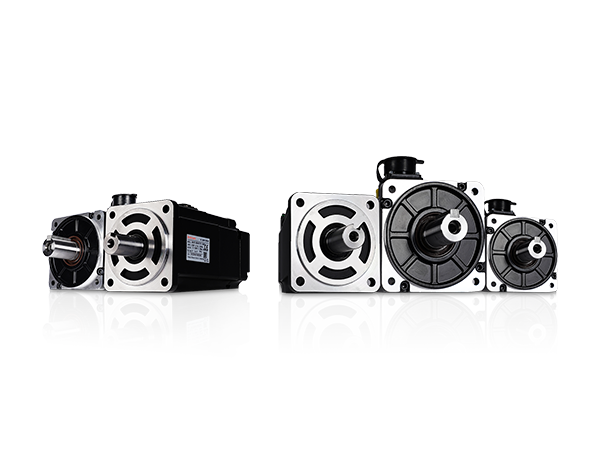

Motor Technology (Induction vs. Synchronous):

-

Induction Motors: The most common type. Standard induction motors may be suitable for simple, light-load applications. However, for precise control or low-speed operation under constant torque, an inverter-duty motor is often required. These motors have enhanced insulation and cooling to withstand the high-frequency switching and voltage spikes generated by the AC drive (PWM control).

-

Synchronous/Permanent Magnet Motors: These require more advanced control algorithms (often vector control) from the AC drive to manage precise speed and torque without 'slip.' The drive must be specifically rated for this motor type.

-

-

Insulation Rating: The motor's insulation class (e.g., NEMA/IEC) must be able to tolerate the voltage spikes and harmonic content produced by the AC drive. Using a non-inverter-rated motor with a modern drive can lead to premature motor failure.

-

Enclosure and Cooling: Standard fan-cooled motors lose cooling capacity at low speeds. For continuous, low-speed, constant-torque applications, the drive/motor combination must account for this, often requiring a dedicated inverter-duty motor with an independent blower or a drive that limits low-speed operation.

2. Electrical Ratings and Compatibility

Matching the core electrical specifications is non-negotiable for safety and operation:

-

Voltage and Power Ratings (HP/kW): The nominal voltage and power rating of the AC drive must match or exceed the motor's nameplate ratings. The drive's output current capability is typically the most critical factor, as it must handle the motor's full-load current (FLA) .

-

Full-Load Amperes (FLA): The continuous current rating of the drive must be equal to or greater than the motor's FLA, especially when operating at the motor's base speed.

-

Input Frequency (50 Hz or 60 Hz): While the AC drive's job is to vary the output frequency, its input section must be compatible with the facility's power supply frequency.

3. Torque and Speed Requirements

The motor's performance curve dictates the type of control required from the AC drive :

-

Torque-Speed Curve (Load Type):

-

Variable Torque: Loads like centrifugal pumps and fans require torque that increases with the square of the speed. Standard motors and simple V/Hz control on the AC drive are often suitable, as less torque is needed at low speeds.

-

Constant Torque: Loads like conveyors, positive displacement pumps, and extruders require the same amount of torque throughout their speed range. This necessitates a more robust AC drive and often an inverter-duty motor to prevent overheating at low speeds.

-

-

Speed Control Range: The required range (e.g., 10:1, 100:1, or even 1000:1) dictates the control technology in the AC drive. Simple V/Hz control provides a limited range, while Sensorless Vector Control (SVC) or Closed-Loop Vector Control (requiring a motor encoder) offers precise, wide-range speed and torque control.

-

Starting Torque: The drive must be sized to provide the necessary torque to accelerate the load from a standstill. This often involves the drive's overload capacity —its ability to deliver higher than rated current for short periods (e.g., 150% for 60 seconds).

4. Feedback and Control Methodology

The motor's configuration often determines the most suitable control mode in the AC drive :

-

Motor Feedback Device:

-

No Feedback (Open-Loop V/Hz or Sensorless Vector): Used for most simple applications. AC drives rely on internal motor models without direct speed or position feedback.

-

Encoder/Resolver (Closed-Loop Vector): Required for applications needing extremely precise speed regulation, torque control, or zero-speed holding capability (like cranes or elevators). The AC drive must have the appropriate terminals and software to process this feedback.

-

-

Motor Poles: The number of poles (2, 4, 6, etc.) determines the motor's synchronous speed at a given frequency, which the AC drive must factor into its control algorithms.

By carefully evaluating these motor characteristics, engineers can ensure the selected AC drive provides the necessary power, protection, and precise control required for the application, maximizing efficiency and minimizing downtime.